Our UFH CAD Design Process

We’ve structured our UFH CAD design process to minimise delays and site queries, while ensuring every layout is calculated and compliant.

Most projects follow a straightforward workflow:

Professional UFH Design for New Build & Retrofit Projects

Contractors often require UFH designs that are:

- in accordance with BS EN1264 and CIBSE Standards

- suitable for multiple floor areas and zones

- coordinated with site timelines

- easy for installers and screeders to follow

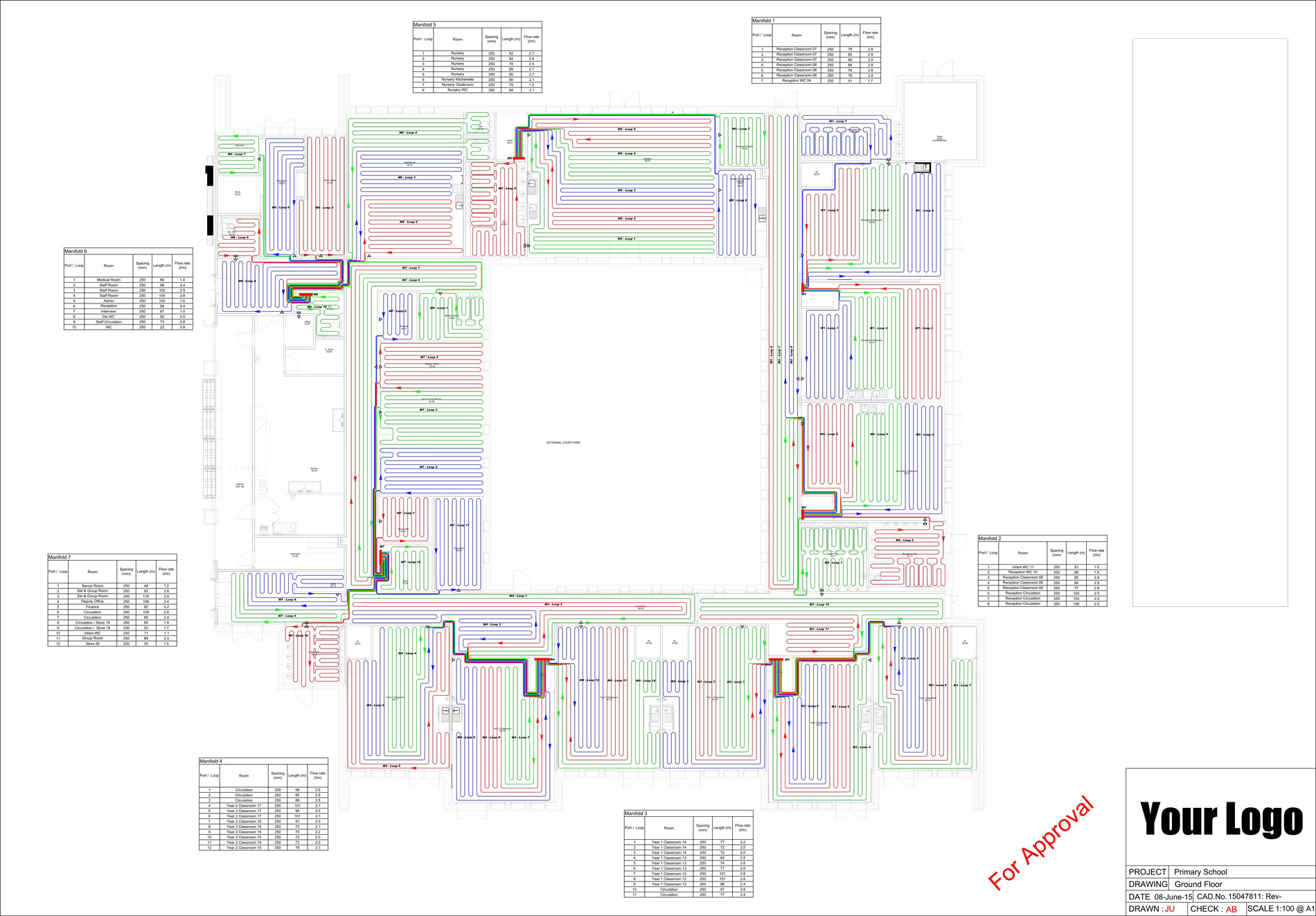

We support projects ranging from single plots to larger commercial floors.

A Simple, Professional UFH Design Workflow

We’ve structured our UFH CAD design process to minimise delays and site queries, while ensuring every layout is calculated and compliant.

Most projects follow a straightforward workflow:

1. Send Us Your Project Information

To begin, we typically require:

- floor plans or drawings

- project type (new build or retrofit)

- floor construction details

- required zones or control preferences

- manifold locations

- heat source

- site timescales and urgency

Clear information upfront allows us to deliver quickly.

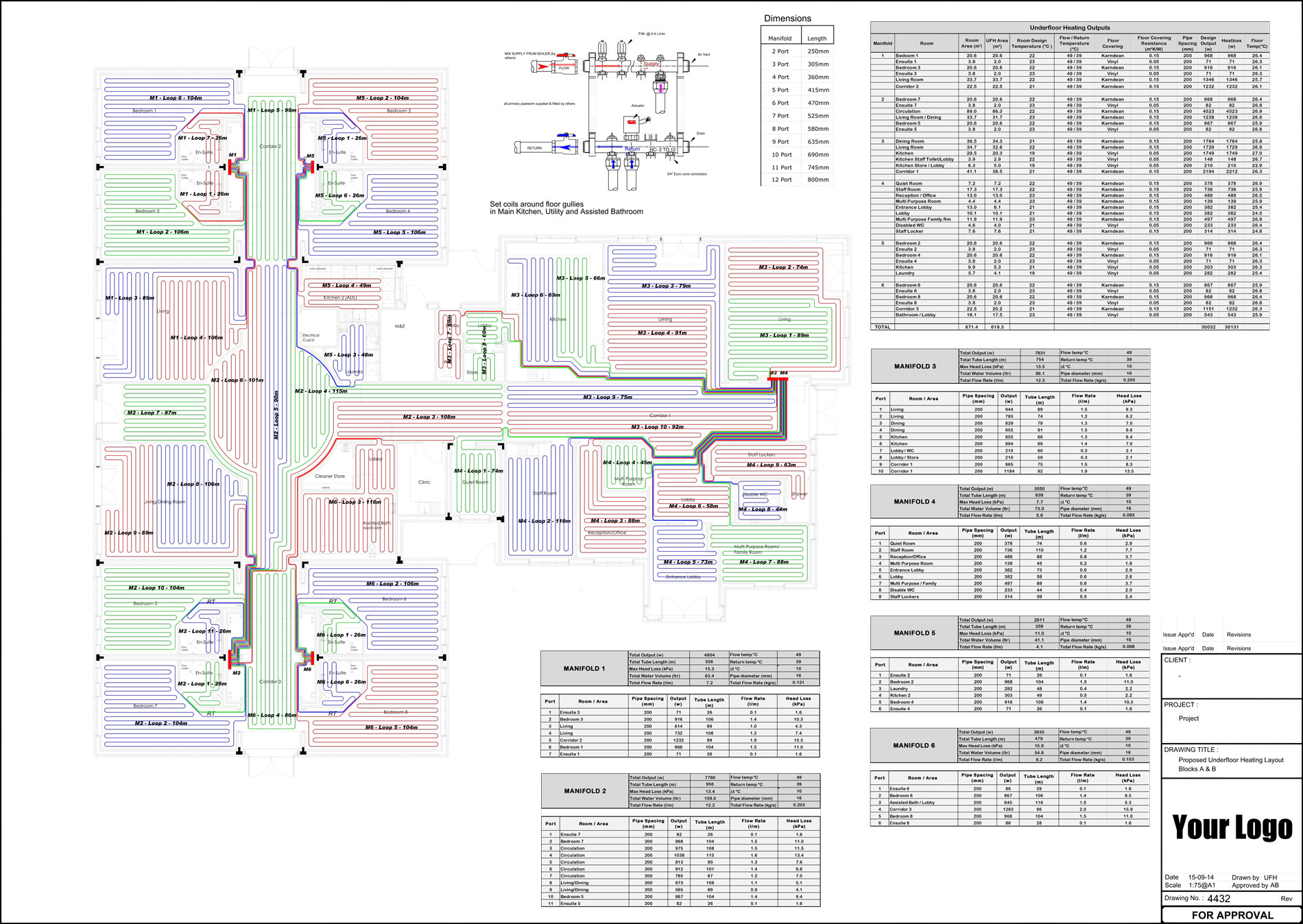

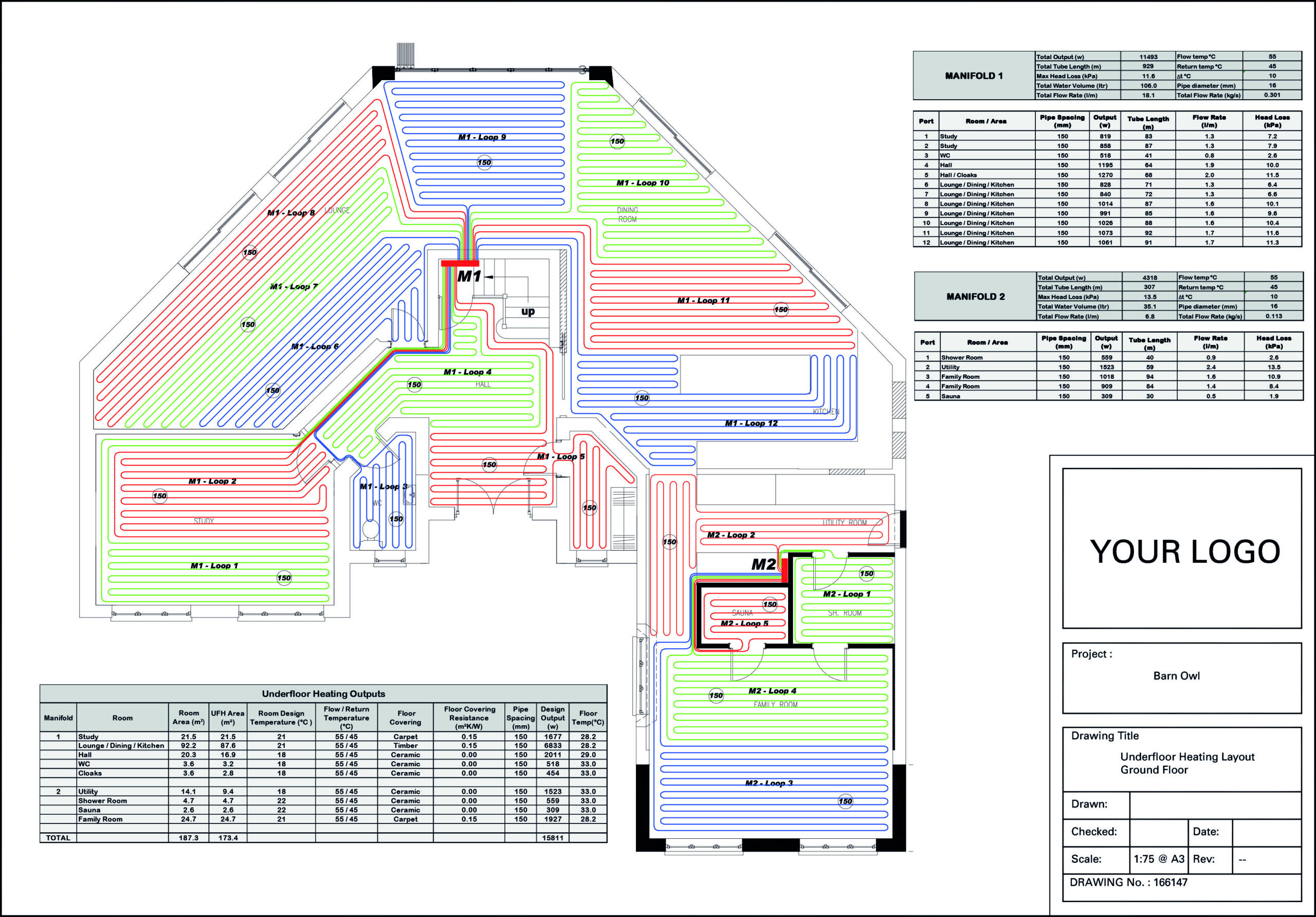

2. Design & Output Calculations

Once received, our in-house team produces:

- engineered pipe layout CAD drawings

- zoning and manifold planning

- heat output and performance calculations

- designs in accordance with BS EN1264 and CIBSE Standards

We do not use generic templates — every design is project-specific.

3. CAD Drawings Issued for Installation

Completed designs are supplied in an installer-friendly format, ready to be handed to:

- UFH System Suppliers

- UFH installers

- Screeding teams

- Contractors

- Client-facing documentation (if required)

4. White-Label Delivery (If Required)

All documentation can be supplied fully white-label, allowing trade clients to issue designs under their own branding.

Designed for Trade Professionals Only

Our process is built specifically for:

- UFH system Suppliers

Installers

Screeding contractors

- Developers and contractors